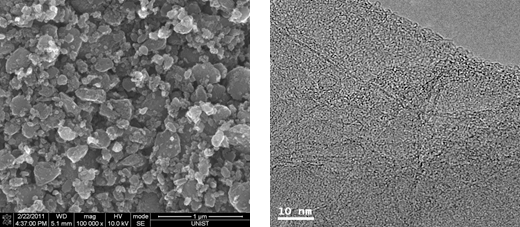

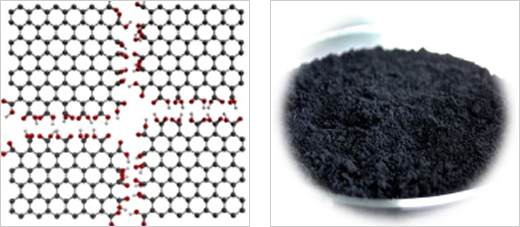

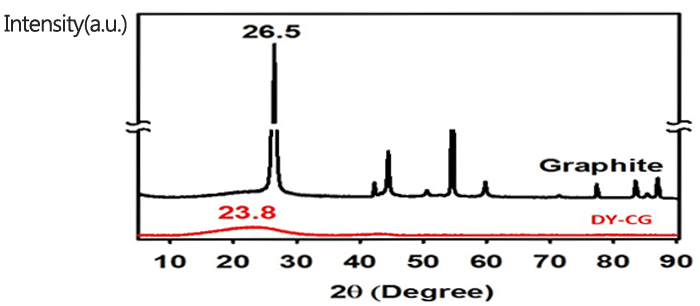

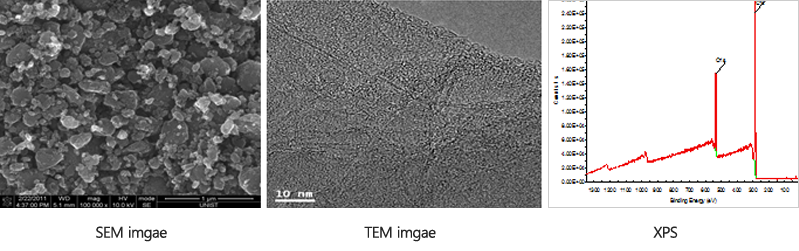

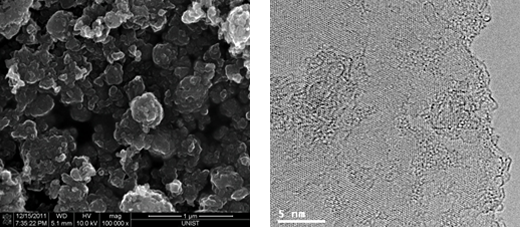

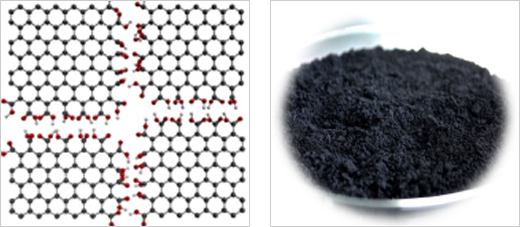

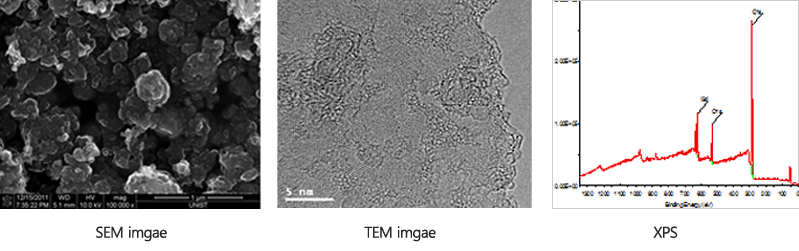

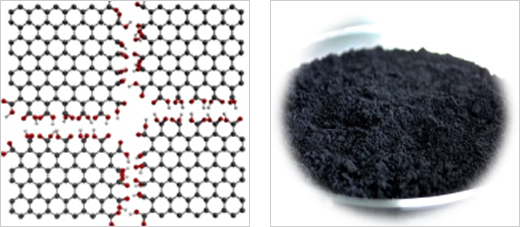

The environmentally friendly graphene DY-Graphene Nano Platelets is produced as an edge-selectively functionalized graphene nano platelets by means of a mechanochemical method on the basal plane without oxidation.

Low-cost, high-yield production of graphene nanosheets is essential for practical applications. We have achieved high yield of edge-selectively carboxylated graphite by a simple ball milling of pristine graphite in the presence of CO2. Ball milling can thus provide simple, but efficient and versatile, and eco-friendly (CO2-capturing) approaches to low-cost mass production of high-quality GNs for applications where GOs have been exploited and beyond.

The environmentally friendly graphene DY-CG is produced as an edge-selective graphite by means of a mechanochemical method on the basal plane without oxidation. Edge-carboxylated DY-CG has better conductivity than that of GO. Furthermore, as a composite, when DY-CG use a carboxyl group, various applications are made possible.

| Product division | |

|---|---|

| DY-CG-A | O content : 15at% |

| Dy-CG-B | O content : 10at% |

| DY-CG-C | O content : 7at%± |

| Element analysis | |

|---|---|

| Element | Atomic % |

| C | 85~93 |

| O | 7~15 |

| Properties | |

|---|---|

| Form | Powder |

| Color | Black |

| Odor | Odorless |

| Particle size | D10 : 0.2㎛ D50 : 1.2㎛ D100 : 3.2㎛ |

| Dispersion | H2O, NMP, IPA etc |

| Dispersibility(0.05mg/mL in NMP) | Z-potential ±30mV |

| Specific surface area | >350m2/g |

| Element | Atomic % |

|---|---|

| C | 85~93 |

| O | 7~15 |

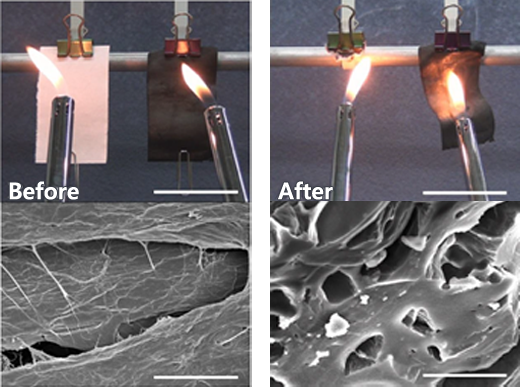

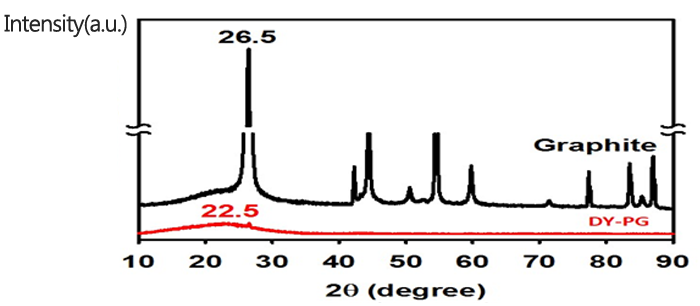

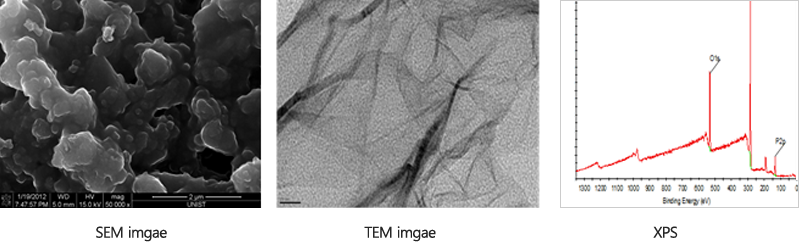

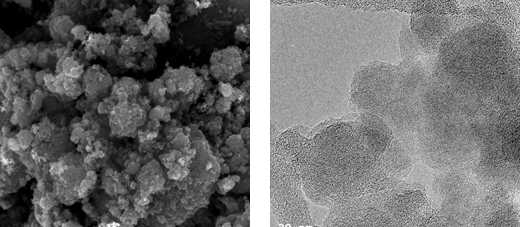

In order to covalently attach phosphorus to the edges of graphene nanoplatelets, graphite is ball-milled with red phosphorus. The cleavage of graphitic C-C bonds during mechanochemical ball-milling generates reactive carbon species, which react with phosphorus in a sealed ball-mill crusher to form graphene phosphorus. PGnP is readily dispersible in many polar solvents, including neutral water, allowing for solution (spray) coating for highperformance, nontoxic flame-retardant applications.

The environmentally friendly graphene DY-PG is produced as an edge-selective graphite by means of a mechanochemical method on the basal plane without oxidation. DY-PG has excellent dispersibility and is widely used in the field of composite materials. In particular, it exhibits excellent properties as flame-retardants.

| Product division | |

|---|---|

| DY-PG-A | P content : 15at% |

| DY-PG-B | P content : 10at% |

| DY-PG-C | P content : 7at% |

| Element analysis | |

|---|---|

| Element | Atomic % |

| C | 54~73 |

| O | 18~31 |

| P | 7~15 |

| Properties | |

|---|---|

| Form | Powder |

| Color | Black |

| Odor | Odorless |

| Particle size | D10 : 0.2㎛ D50 : 1.2㎛ D100 : 3.2㎛ |

| Dispersion | H2O, NMP, IPA etc |

| Dispersibility(0.05mg/mL in H₂O) | Z-potential ±30mV |

| Specific surface area | 100㎡/g |

| Element | Atomic % |

|---|---|

| C | 54~73 |

| O | 18~31 |

| P | 7~15 |

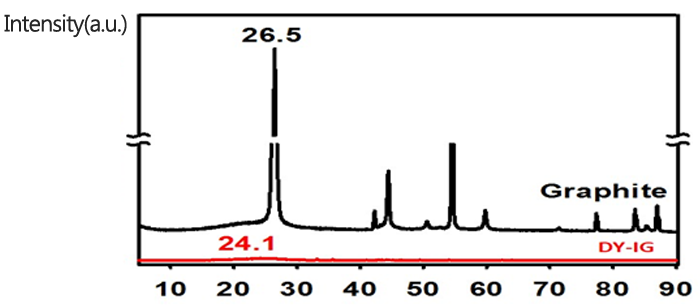

DY-IG has remarkable electrocatalytic activities toward oxygen reduction reaction(ORR) with a high selectivity, good tolerance to methanol crossover/CO poisoning effects, and excellent long-term cycle stability.

The environmentally friendly graphene DY-IG is produced as an edge-selective graphite by means of a mechanochemical method on the basal plane without oxidation. The newly-developed DY-IG can be well dispersed in various solvents, and hence are solution processable.

| Product division | |

|---|---|

| DY-IG-A | I content : >0.5at% |

| Dy-IG-B | I content : < 0.5at% |

| Properties | |

|---|---|

| Form | Powder |

| Color | Black |

| Odor | Odorless |

| Particle size | D10 : 0.2㎛ D50 : 1.2㎛ D100 : 3.2㎛ |

| Dispersion | H2O, NMP, IPA etc |

| Dispersibility(0.05mg/mL in H₂O) | Z-potential ±30mV |

| Specific surface area | >600㎡/g |

| Element | Atomic % |

|---|---|

| C | 88~94 |

| O | 6~10 |

| P | 0.5~2 |

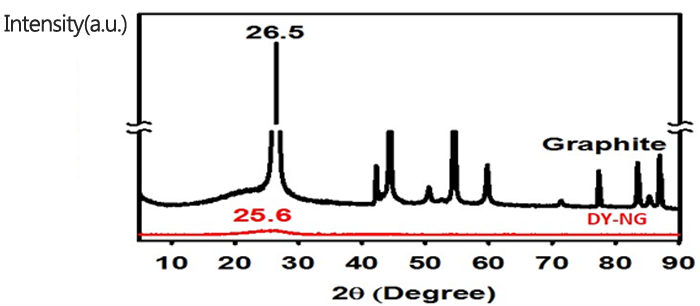

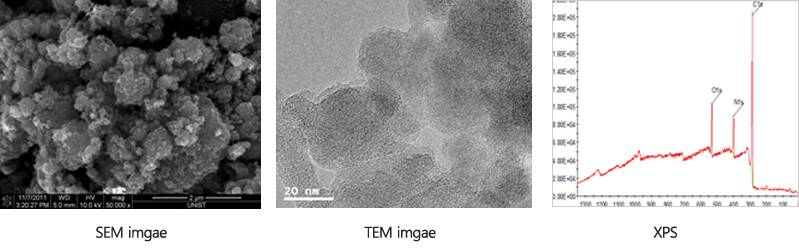

However, direct nitrogen fixation is challenging as nitrogen (N2) does not easily react with other chemicals. By dry ball-milling graphite with N2, we can produce a simple, but versatile, scalable and eco-friendly, approach to direct fixation of N2 at the edges of graphene nanoplatelets (GnPs).

The environmentally friendly graphene DY-NG is produced as an edge-selective graphite by means of a mechanochemical method on the basal plane without oxidation.

DY-NG with superb catalytic performance in both dye-sensitized solar cells and fuel cells can replace conventional Pt-based catalysts for energy conversion.

| Product division | |

|---|---|

| DY-NG-A | N content : 15at% |

| Dy-NG-B | N content : 10at% |

| DY-NG-C | N content : 7at%± |

| Properties | |

|---|---|

| Form | Powder |

| Color | Black |

| Odor | Odorless |

| Particle size | D10 : 0.2㎛ D50 : 1.2㎛ D100 : 3.2㎛ |

| Dispersion | H2O, NMP, IPA etc |

| Dispersibility(0.05mg/mL in H₂O) | Z-potential ±30mV |

| Specific surface area | >100㎡/g |

| Element | Atomic % |

|---|---|

| C | 72~84 |

| O | 9~13 |

| P | 7~15 |